This year’s prep began the day we landed from Reno 2017. We had just pushed the plane faster than ever, and my inadvertent mixture bump caused us to pull up from the Gold Race on Sunday. The good news was we didn’t break anything and had a great baseline.

We started with the engine overhaul to see how the new piston fit was working and if the high power had caused any cranktrain or crankcase issues. We were pleasantly surprised as the engine looked great inside. The team at Pinnacle Engines in Alabama continued the rebuild process, while we were busy back in Virginia. Matt Sparck welded up the rotisserie that was attached to the front of the plane, allowing us to easily rotate the fuselage and repair the areas that were damaged by the hot exhaust during augmenter development. While the plane was inverted, we reinstalled the wing and began a big project to eliminate the hinges on the fowler flaps and install a piano hinge flap similar to the Lancair 360. Tom McNerney had just completed this project on his Super Legacy build so he came out for a few days to help get the process started. This involved a lot of carbon fiber layups to get the structure to attach to the rear spar.

Sean and Tom sanding the stock flaps

First movement of the piano hinge flaps

Success! Sanded down, time to prime

After the flap mod and belly repair were complete we primed the bottom surfaces and flipped the plane over for the engine install. We cleaned and powder coated the engine mount and installed carbon fiber gear doors from Tom McNernery. Once the engine was on, we made a new intake system to reduce the length and bends out of the turbo leading to the throttle body.

Matt Sparck’s welding skills brought the new idea to life

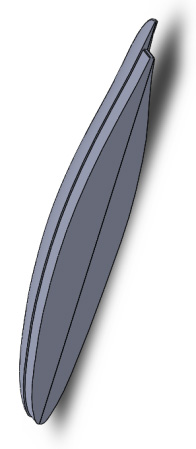

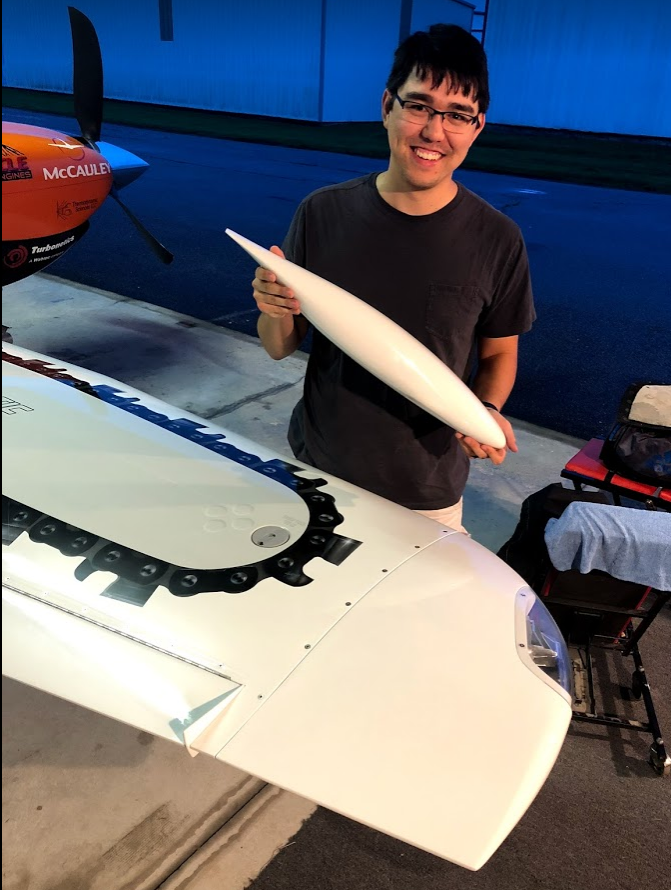

After the engine was on, we did some break-in flights and baseline testing before heading to see Brad Simmons at Airframes Inc. for the new graphics and paint. While the plane was stripped down the body work was smoothed out, gaps filled, and the wings profiled to the correct airfoil. We also made the wingtips removable so the small caps could be installed. The caps reduce the total span by 2 ft., (See wingtip article posted on the site for more detail.)

Young Thomas displaying the new tips after we cut 12″ off each wing

It was time to start laying down the graphics and scheme. We preprinted masks for all the logos so they could be under the clear and the profile perfectly smooth. The wing layout was going to incorporate the chainsaws again so Jerry and crew masked the big parts and then airbrushed all the details. It turned out amazing!

The detail in the chainsaw is incredible!

We brought the plane home at the end of July and the final prep work was in full swing. We got some larger injectors from Five-O-Motorsports and I remapped the SDS EFI system to match. This gave us more margin at the high boost levels to keep from reaching 100% duty cycle on the injectors when the boost is turned way up!

We headed to Wichita to do some prop testing with the McCauley Blackworks team. They had designed a few tweaks for a new prop and we wanted to validate the model with some flight testing. We did lots of testing with the existing prop and the newly designed prop and developed the drag curves for each at multiple power settings. The top speed was within a knot, however the new prop was better at takeoff and climb so we chose that. It was nice to have a little more low-speed performance with the clipped wings.

We headed back home to continue testing and figure out why the ADI was intermittent in Wichita. As we were testing, the engine was surging and didn’t want to make boost over 50”. It appeared to be an airflow issue as the turbo spooled, but wasn’t clear. We finally tracked it down to a leak in the ADI controller. The leak was causing the MAP sensors to receive bad readings and then start chasing themselves as the boost came on. Thomas Lindgens came to the rescue and rewired the ADI system (again) to use pressure switches and we continued testing.

We had a few cylinders still getting hot at the higher power setting so it was time for more water. Mark Voss came from Alabama and made a new spray bar system, which more than doubled our flow rate potential. This created a challenge for carrying enough water, so it was time to take a trick from the Unlimited’s playbook and convert the left wing to hold water. We added a few more cylinder baffles and the combination brought the CHT trends together at race power.

Everything was now working nicely and we were ready for Reno! Charlie (the flying Cavalier) and I left Thursday planning to stop at Tom’s for the night, but as we got close the weather looked bad the next few days so we fueled up and headed west. The winds were great up high and we were doing 250 kts groundspeed westbound. We made it to Pete Z’s for the evening. Friday was a quick hop to Stead where we met Jackie and Bob to start setting up the pits. My dad arrived shortly after with the trailer from Idaho.

Saturday we finished the rookie training for PRS that was cut short by the runway construction and high winds back in June. It was great to get out on the track and get a few laps in.

During Sunday’s practice, we started turning up the boost but the firefighting aircraft ops kept us off the course for our period. The Unlimited’s were going around Peavine before their course time so I requested us to go back on the course. They obliged and we headed back down to see how the power settings looked. When I added power the engine got really lean and wasn’t responding to mixture changes. #6 Cylinder Head Temperature (CHT) was getting hot fast so I decided to pull up, not realizing the unlimiteds were going directly over the valley of speed. I dodged a few P51’s and got up into cooldown, #6 still hot. I knew that meant we hurt the piston and headed back to start the repairs. On rollout a big puff of smoke followed me in so I knew it wasn’t happy.

#6 got lean and damaged the piston

Muratic acid to remove aluminum before honing

Piston failure and overnight rebuild

Mike and I spent the evening cleaning the aluminum off the cylinder with muriatic acid, honing the cylinder and putting a fresh piston in. Monday am we did a quick test run to check for leaks and got ready for the test flight. I went up with the flight but just orbited overhead to get some time on the rings and cylinder. The afternoon session was bumpy, but the engine was stable so I called for the clock to get a time. The qualifying laps weren’t at full power, but I didn’t want to worry about having to get a time Tuesday if there was another piston issue. The qualifying time turned out pretty good at 388 mph, faster than we had ever been before! Good news for the team!

Now that we had a qual time, we could just focus on testing. The settings we had in Virginia (humid, dense air) didn’t match the dry conditions in Reno so we continued to dial in the spray cooling, mixture setting, cylinder trims and boost levels. Tuesday flights went well and we tested the higher boost on Wednesday AM. We did a few laps at 397 mph, so close to 400 mph, but not quite. We backed down the boost for the beginning of the week, but had a good setup for the Sunday final.

Jeff qualified at 407 mph, a new personal best for him with the current course length. We started second, but were able to hang with Jeff and even get next to him for a bit. As we got into lap traffic I stayed wide and lost some time, but we finished within a second of Jeff with a 383 mph average. After we landed, Jeff was excited we had a good race, the whole sport class was stoked, and the crew was jumping up and down. It was great to fly with Jeff at speed and build some trust flying close.

That evening we did a flight for John Parker. Parker’s longtime Crew Chief, Mike Cummings, flew with me as we did the missing man over the American Air Racing hangar. It was an emotional sendoff. We miss John, but his contribution to racing will never be forgotten.

We were excited for the Friday race after getting next to Jeff on Thursday. We had a good start, but after the release, I noticed the intake temperature getting hot. No ADI! I flipped the auto system to manual ON, but still no ADI. Temps are getting really hot so I backed off the throttle, to prevent engine damage. The rest of the race was just cruising, and Jeff lapped us. Arrr, so frustrating! When I got on the ground, I tested the system again and it worked fine. We did an evening test flight and it worked fine as well. After some troubleshooting, it appeared the ADI pumps got air in them during the Thursday evening flight and didn’t want to prime on Friday when the boost was up. Lesson learned!

Saturday we had to start on the outside after going “slow” on Friday. We got a good start, passing the other planes before the guide pylon and passing Bob Mills before the Valley of Speed. Now it was time to focus on the line to catch Jeff. Lap two we are next to Jeff in the Valley of Speed, holding a tight position coming by home pylon with some altitude to spare.

Coming up the hill past pylon three, pushing that altitude down, and we get in front of Jeff! The winds were high so it was bumpy but we had a clean track and held the position.

We had pole position for the Sunday Gold race!

The pass

Our first team firetruck ride!

Sunday we double checked all the systems and were ready for the big race. This was our first time on the pole and everyone was excited to see the shootout of the two Turbonetics twin-turbo boosted planes. It was full of rivalries, Continental vs Lycoming, Glasair vs Lancair, McCauley vs Hartzell, the energy was amazing!

During the pre-race brief, we dedicated the race to our friend, mentor, and legend John Parker.

We hopped in the plane and the engines roared to life. A quick taxi down past the grandstands and it was time to push it up. As the pace plane came past the racers, we all gave the final thumbs up and we are ready to roll!

Jeff had a nose gear retraction issue and had to cycle it a few times before joining the flight behind Pevine. Mark “Magic” Johnson, in the pace plane, called us line abreast into the chute and the course was in sight. Speed is coming up, power is increasing. The L39 is at full power down the chute, 225, 250, 275 kts he calls out as we wait in anticipation. Then the famous words, “Gentleman, you have a race!”

I pushed the power all the way up and the engine surges, the turbos are spooling up, the ADI comes on and the spray bars are on full blast. The engine is not happy and it sounds like the exhaust blew off again, but I held steady to see if it would smooth out. Visible streams of mist are seen behind Jeff and me as we pull for every bit of power out of our engines.

Holding the line to the guide pylon I see the temps are stable and catch the speed out of the corner of my eye, 350 kts across the ground, we are moving fast! We roll into pylon four, past five and start unloading the “G” into the Valley of Speed. Temperatures are climbing with all the power and the speed continues to build, over 375 knots down the valley and we roll into the turn coming by the crowd and home pylon.

Cylinder #6 is getting hot, it was the cylinder that stuck last Sunday, so I richen it with fuel to cool it down. No luck as the CHT passes 420F. I continue to globally richen the engine to help the temps and it reaches 430F. I don’t like the temperature trend (435, 436, 437…) so I reduce the rpm a bit, and get it to stabilize and it starts a downward trend. Now I can focus on flying a smooth line with everything stable. The rest of the CHT’s are below 400F, the intake temp is stable and oil temp is a cool 192F.

The air is smooth out front and I check for the shadows coming past pylon seven, it’s just me. I hear Mike on the radio, “four second lead, eight second lead.” We are gaining! I stay focused and hit my turning points. The crew on the ground is timing laps and we are consistently over 400 mph, with the best time of 1 min and 9.9 seconds. A 407 mph lap!

The ground is speeding by, over two football fields per second, but I am in the zone, with everything happening in slow motion. The plane is on rails coming past the pylons and I hear “white flag, white flag.” One lap to go, stay focused, and stay smooth. The last time in the Valley of Speed, we are doing 375 kts groundspeed! I come by Home Pylon and see the checkered flag waving. We have done it! “Checkered Flag, Checkered Flag” I get the nose pointed up and start gaining some altitude.

Back into Cooldown, I try to keep the engine happy. Going from the big boost with ADI to cruise power can be tricky. As I reduce power, roll back the rpm and make sure the spray is off, it stumbles a bit, but smooths out. I hear the pace plane call that someone is trailing smoke, and then they confirm it’s Race 39. Jeff is a true competitor and was pushing his engine to the end, but as he pulled into Cooldown, the engine had enough and pushed the oil out of the crank seal. He calls “mayday” and turns for runway 14. The lack of oil caused the engine to seize and he pushes the nose down to maintain best glide. I see his shadow getting close as he barely makes it to the end of runway 14. Great piloting to bring it in safe!

I do one more lap in cooldown and head in for landing. Rolling off the runway, I see the Sport Class family all on the ramp, so excited for the amazing week we have all had. As we are celebrating, Tom comes up and said, “Dude, you broke 400 mph, in a race!” Race average was 402.716 mph!

Everyone is safe, we had some remarkable racing, and the team set a new speed record, this is what Reno is all about! So much respect for the great competitor that Jeff is, and the greats that have come before us as we chased speed legends of Darryl Greenamyer, Jon Sharp and John Parker.

Thanks to the team, my family and all the sponsors that make this dream a reality! Time to start finding more micro knots! #speedmodseason has begun!