It would be an understatement to say it’s been a crazy two years. While it was a bummer that the Covid-19 pandemic cancelled the 2020 races, it was understandable given the travel and safety concerns of the teams and fans. Fortunately, RARA, STOL Drag’s Trent Palmer and hundreds of fans all chipped in to raise $500,000 for the 2021 races. And after taking a year off this year’s races were definitely worth the wait. Also, a shout out to Kevin Quinn and the STOL Drag pilots who have done an amazing job revitalizing general aviation and getting people excited about flying together. If you haven’t seen their events, check them out and the High Sierra Fly In and STOL Drag events across the country.

New Panel and Electrical System

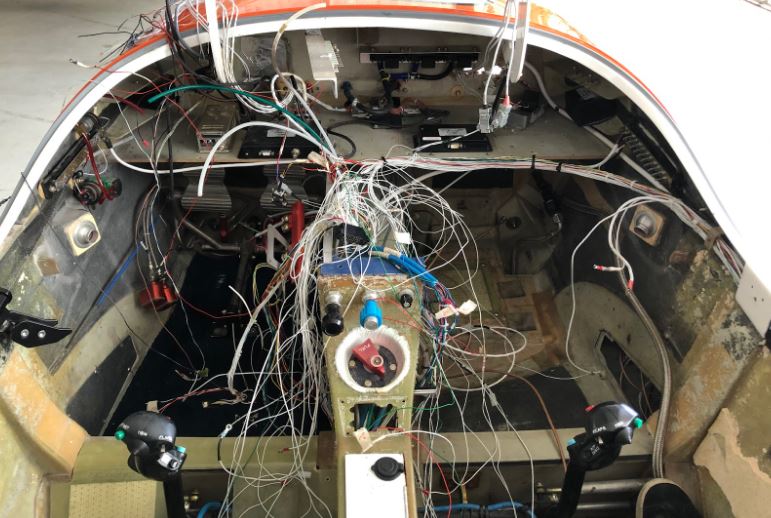

The team took full advantage of the extra time by ripping out and replacing the panel and the entire electrical system. In 2019 while on a photo flight at PRS the plane suffered a power failure forcing an off-field landing on a nearby road. When we got home we found that a failure of the primary battery could drain the backup battery with it. This systemic issue coupled with the fact that so much had changed over seven years of racing, meant it was as good a time as any to start from scratch. Also with no heat in the legacy, my favorite speed mod was seat heaters for the long cross country flights up high!

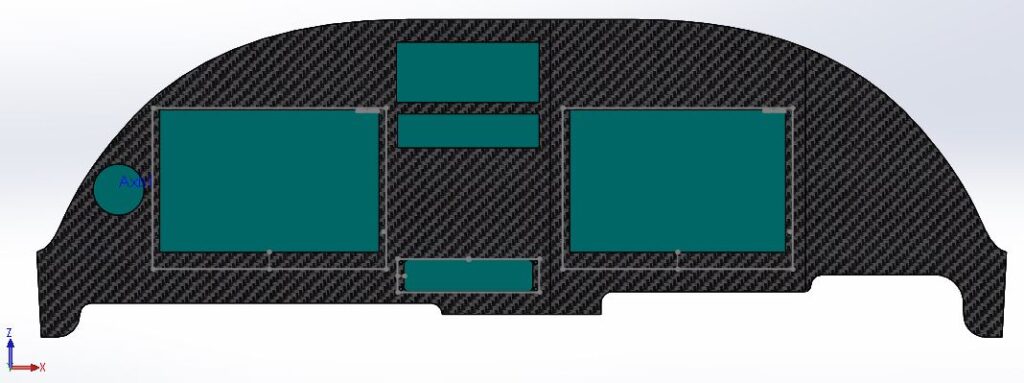

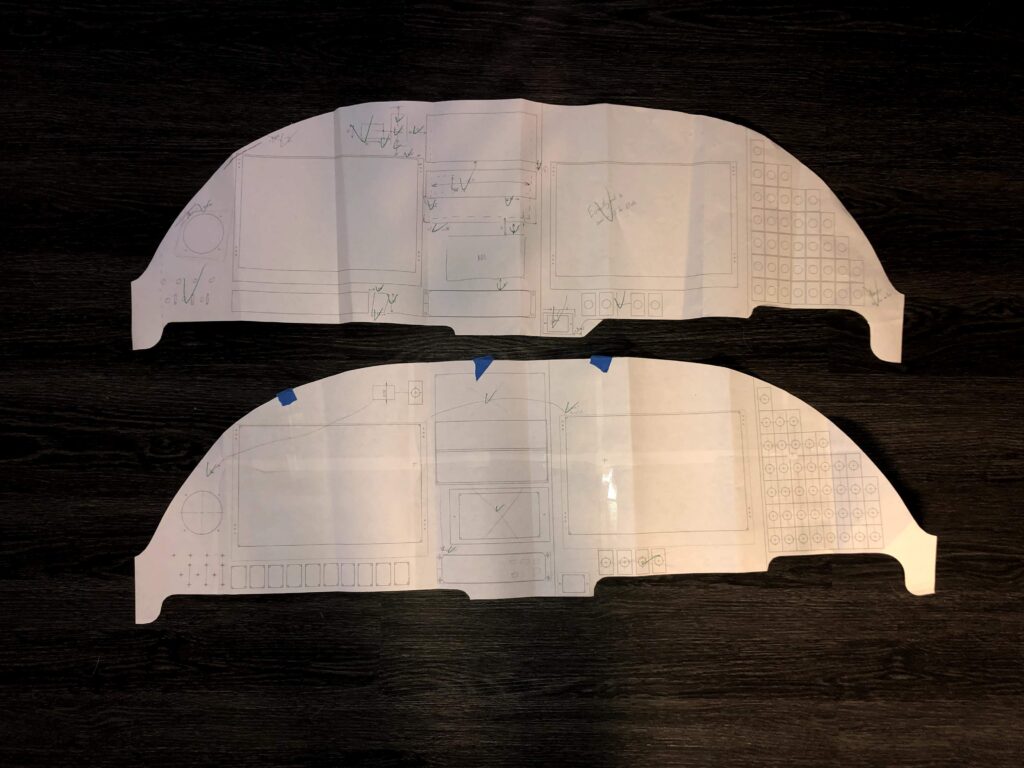

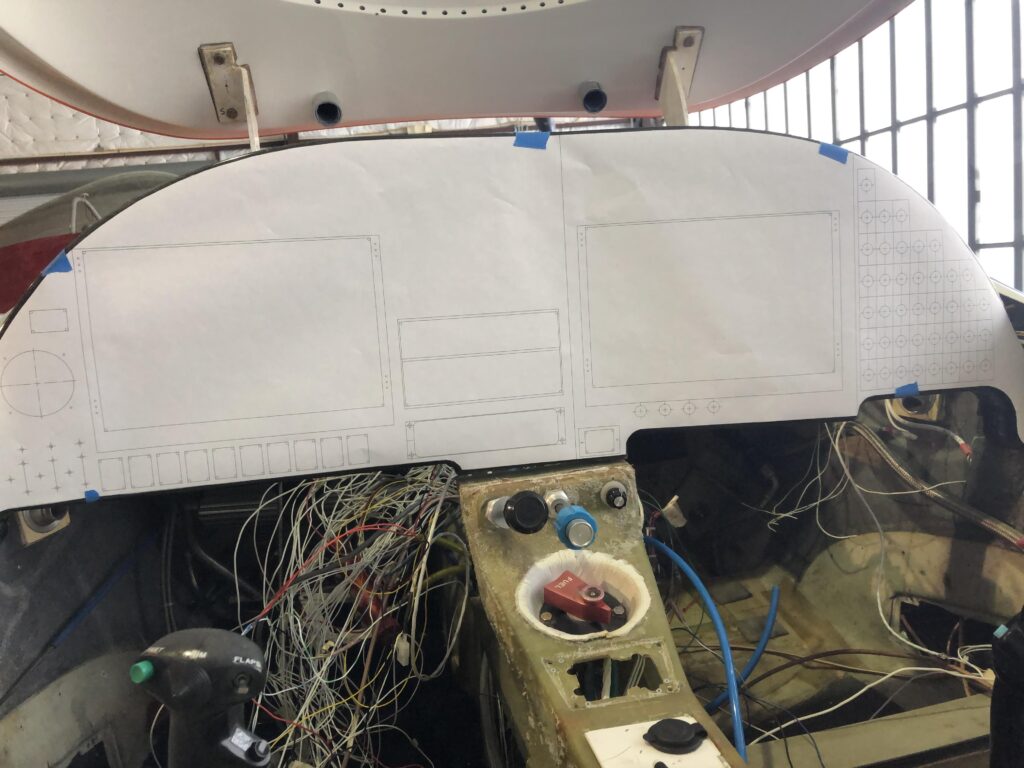

Tom McNerney sent us a new carbon fiber panel modeled off the panel in his own Super Legacy project. Young Thomas then modeled the whole panel, monitors, and switches in CAD and printed full scale paper templates. This let us try everything out and reach for all the buttons and race systems to make sure everything felt right.

We updated the SDS EFI controller to the new rectangular layout and added the XIC controller to manage the ADI. This automation reduces the workload to manage the engine dramatically from the old mechanical systems. Being able to trim cylinders individually is also a big benefit to keeping the engine together at high power.

Engine Rebuild

As the panel was getting wrapped up we received a fresh engine from Pinnacle Aircraft Engines in Alabama. The inspection of the 2019 engine looked great so we stuck with the same recipe for this year’s engine. Mark has calculated we are fatiguing parts of the crankshaft at our high power levels so we put a new crank in the engine every 2 years. The new piston fit looks great at the high power. The bearings and cases also looked good for the high power. To dress up the engine a bit, JD painted the engine to match the plane, looks great!

PRS

After taking 2020 off, it was great to be back for PRS. I really enjoy this week because we get to do so much formation flying, and aren’t trying to break anything pushing lots of power. The week was split into 2 groups, allowing us to get additional course time. I managed to combine a few groups and we had a 55min session on the course. These sessions are great for working different lines, practicing formation with others, and setting up some great passes for the photographers at the pylons.

I help present the ground school portion of PRS. I really enjoy sharing the challenges, techniques, and safety aspects of racing. If you want to check it out and come race, the material is on the sport class website.

New Propeller

The most obvious speed mod was the new 4 blade propeller from McCauley. You can read more about the technical aspects along with the tradeoffs of adding more blades here. We got the propeller installed after PRS to collect vibration and stress and strain data. This allowed the team at McCauley to verify their performance calculations and that everything was safe (this process was done for the 3 blade propeller in 2016).

The testing in July was completed with full power runs so it was an early chance to make sure the calibration was dialed in. The new ADI system from SDS EFI was working great with the high power transitions and all the other power levels tested during the vibration survey.

After the propeller was tested in Wichita, it was time to remove it and send the blades to Brad Simmons at Airframes Inc to match the paint to the plane. As usual he did an incredible job!

Oshkosh

While the prop was being painted, our intern Nicolas Lu and I went to OSH. Work was busy so we didn’t have time to do the AirVenture cup, but Joe Corragio got us a premium parking spot with the other AVC racers.

It was Nicolas’ first time to OSH so we did the quick tour of seeing as much as we could, and say hi to all the aviation friends and family we didn’t get to see last year. OSH was very busy but we had to cut the trip short due to a thunderstorm that was forecasting hail.

Final Prep and Qual

Since we had done the vib survey in July, the August calibration work was pretty minimal and the speeds up high looked great. Back on the east coast we were doing some final testing to make sure everything was perfect.

The 4-blade prop requires a larger spinner. In order to get a smooth transition from the spinner to the cowling, we needed to make a new fairing. We 3D scanned the cowling and Tom McNerney and Laminar Consulting LLC used those files to CNC the molds and do the initial layups. Then with the help of Ed Smith and Young Thomas we did the final trim and fit up.

During flight testing we noticed some fluctuation in the ADI (anti-detonation injection) pressure. We adjusted the regulator, but didn’t see any change in the pressure. So we opened it up and found one of the hose fittings was interfering with the spring and membrane. This was an easy fix and stabilized the ADI pressure. We also noticed a small intake leak and put on a different intake clamp. These easy “fixes” turned out to be a major change to the calibration. During practice and qualifying the engine was surging and I was puzzled because it was transitioning so well before. During my qual lap it took 3 tries to get it spooled up and it quit twice down on the course. After a few long nights looking at data and scratching our heads, it realized it was the “fixes”. The intake leak helped to keep the turbos from surging and the regulator fix was adding 30-40% more fluid to the intake. Luckily by Thursday we had it figured out and were ready to go, but it was a good lesson learned.

Race week

An interesting development in the class was everyone ditching intercoolers in favor of just using ADI. This provides the same cooling performance but with less weight, less cooling drag, and less pressure drop in the intake system. Going all the way back to WWII, ADI has historically been a 50/50 (by volume) mixture of water and methanol, but this year teams were also experimenting with different mixture ratios. The methanol chemically lowers the freezing point of the mixture, but given how hot it gets in Reno and how low we are flying, that really isn’t a concern. And given that water has the highest latent heat of vaporization, using a higher percentage of water means we will have a more effective cooling system.

Qualifying was a tight race for pole position with the top three Sport planes finishing just under the 400mph mark. It was shaping up to be a fast and competitive week of racing assuming everyone kept their engines together.

Also this was an amazing year for Jim Rust, Robbie Grove, and Race #24. In addition to taking the pole, their qualifying speed of 396.6mph was 17mph faster than their speed of 379.6 in 2019. This was the biggest speed gain of anyone in the class and earned them the Rocketeer award.

Thursday Heat 1A

We were starting and third and dove after Jim and Jeff onto the course. Following is tough because while you are still trying to fly a smooth line to minimize Gs you also have to fly off the planes in front. I stayed up high and out of their wake for the first five laps. On the last lap, going into the back side of the course Jim and Jeff swung wide around pylon 4. I had been watching their line the previous laps and building up some altitude. As we rounded pylon 4 I pulled inside and traded my altitude for airspeed. This added momentum carried me all the way down the Valley of Speed and I only just missed passing Jim at the end. No power changes were made in the last lap. All the added momentum came from managing aircraft energy and working the racing line.

It was a great way to start the week after missing 2020. In the debrief we reviewed the inside pass on Jeff. Since I was down low and way inside of them, Jeff confirmed he had me insight as I made the pass and closed on Jim.

Friday Heat 2A

Friday started out much like Thursday with Jim, Jeff, and I all within a second (about two football fields) of each other. Starting in second I had the advantage of only having to fly off of one plane instead of two. The strategy was the same as before, stay up high in clean air, work the race line, and conserve energy. By lap 4 I had closed up to Jim’s wingtip and with a dive into the valley was able to complete the pass. Good to be back in front!

Getting back into Pole Position was a great way to start our Friday evening and our team/sponsor appreciation dinner. There are so many great people that make it all happen, and it was great to be back after two long years.

Saturday

For Saturday we had a higher power setting picked out. The telemetry from Saturday’s race would be important when deciding how much we could increase the power for Sunday. Unfortunately, the 39kt winds exceeded the safety limit for Sport Class (35 kts), and we had to scratch Heat 3A.

Sunday Sport Gold

Having to scratch on Saturday left us with a difficult choice. We could run the still-untested power setting from Saturday or we could double down and increase the power even more. If we stuck with Saturday’s setting and lost, then we would always wonder what might have happened if we increased the power. But if we increased the power and broke the engine it would appear that we had been greedy and thrown away a win. In the end we decided to be conservative and stick with Saturday’s setting.

Coming down the chute Jeff got a great start on the outside similar to how I passed him in in 2018. As we started into the first turn I saw Jim starting to turn when he dropped below my canopy line. Having lost sight of him and being uncomfortable with the rate of closure, I turned early cutting inside of pylon 4. The engine ran great for the next six laps and I was able to open a small gap to Jim. But ultimately I wasn’t able to close the gap to Jeff. After the race we appealed the pylon cut, since it was done out of safety, but our appeal was overruled. So in the end we received a 12 second penalty (2 seconds multiplied by 6 laps) which dropped us into 3rd.

Overall it was an amazing week of racing. Over the course of three races Sport Gold had three different winners. All week long we pushed a crazy amount of power with no mechanical failures (even the oil filter was spotless!). Everyone really has their systems dialed in and are truly pushing their airplanes to the limit. And that’s what Reno is all about! Time to get back to #speedmodseason and find some more micro knots, or just more boost! Haha!

Thanks to everyone on the team, and our sponsors that allow us to compete at the top!